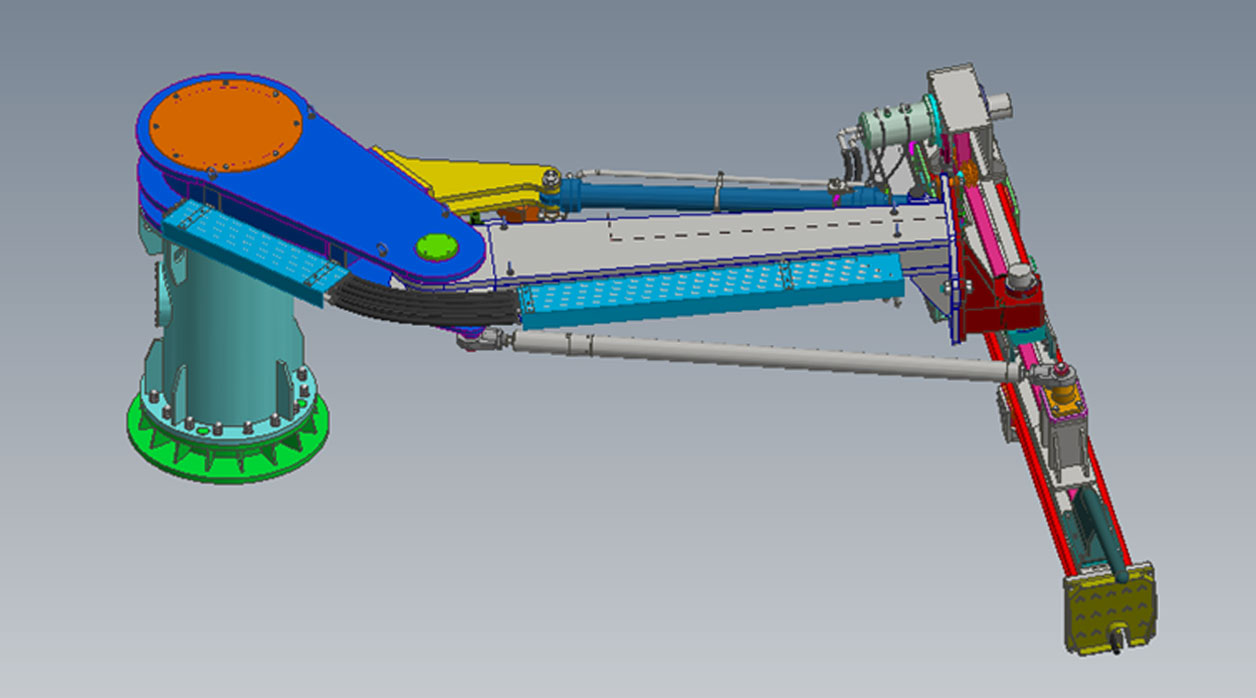

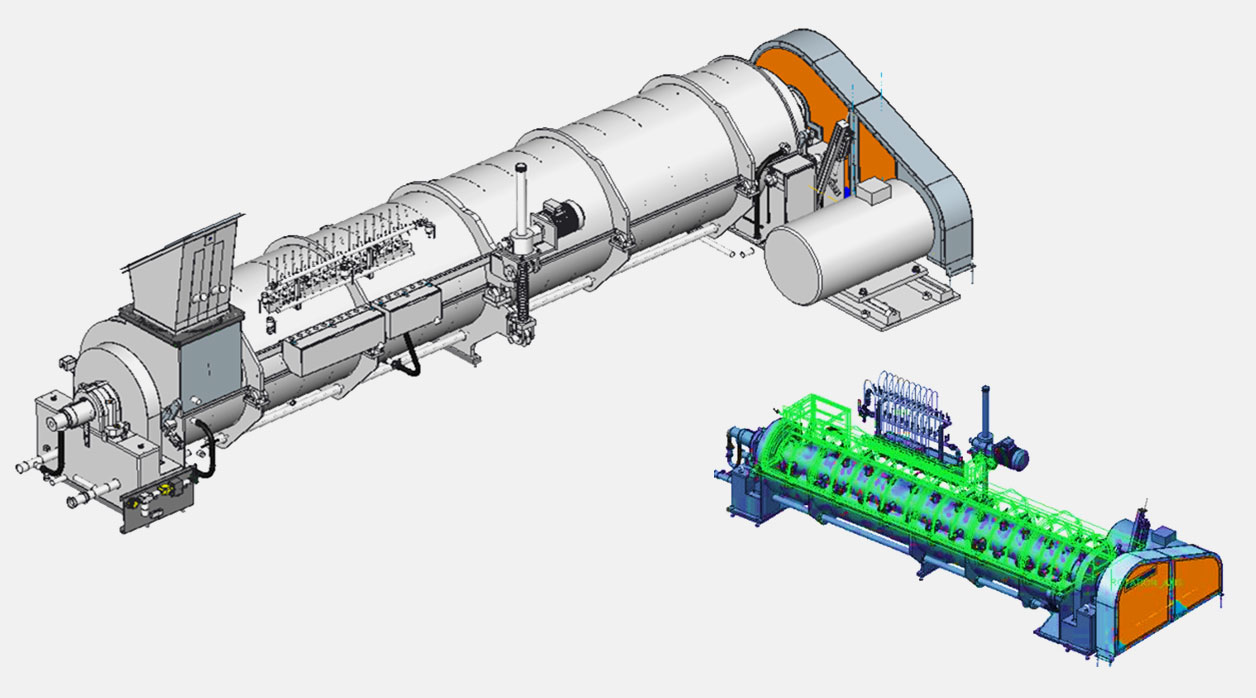

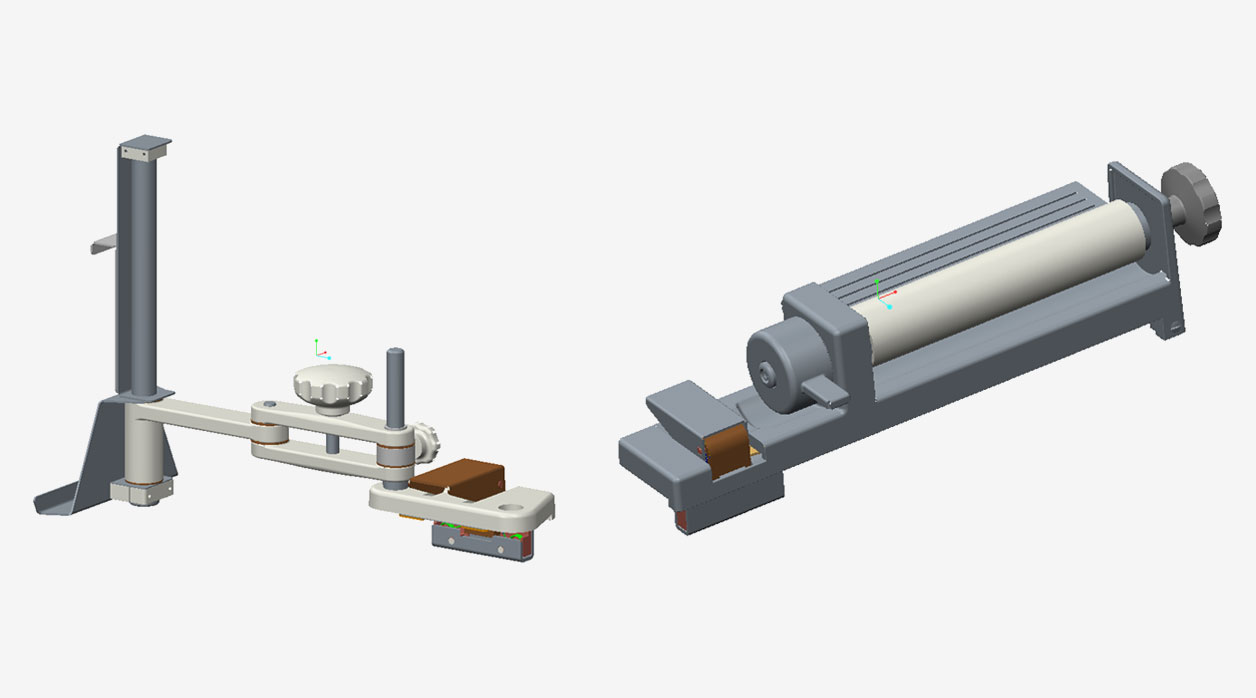

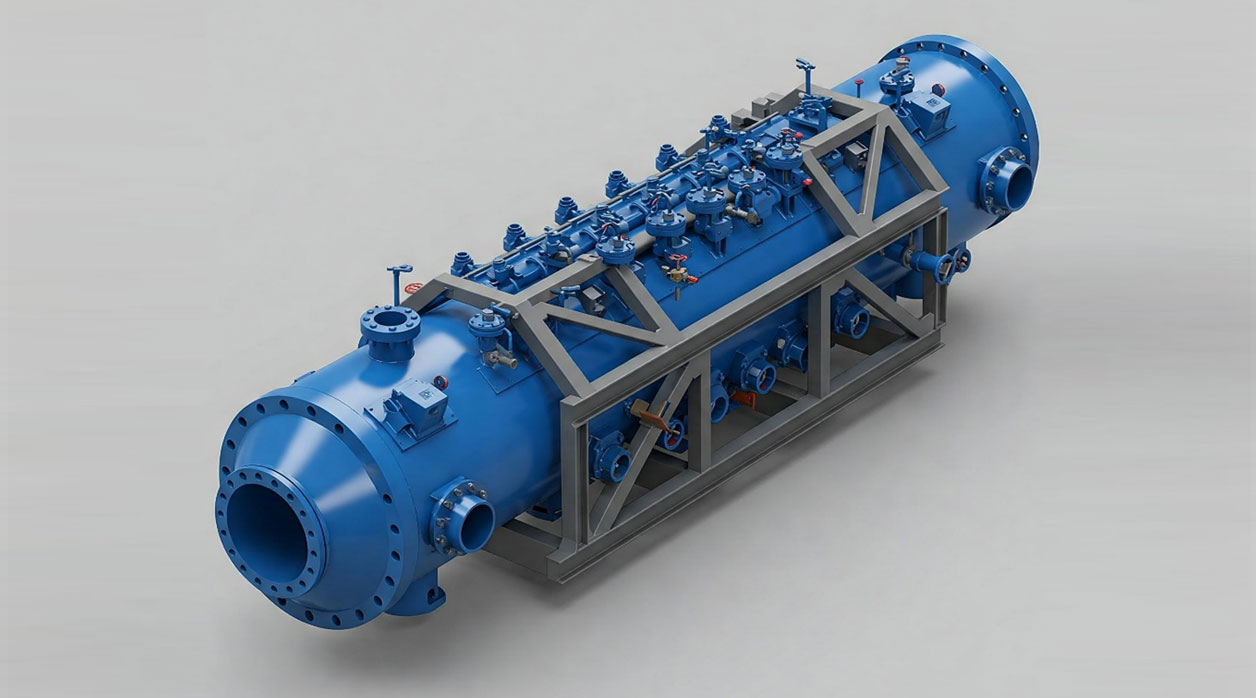

We did an R&D project for a global leader in the metal industry. We led a product development project and designed cast house tapping equipment, including a drill machine and a clay gun, specifically for operating tap holes on a blast furnace at around 1400°C with CO presence.

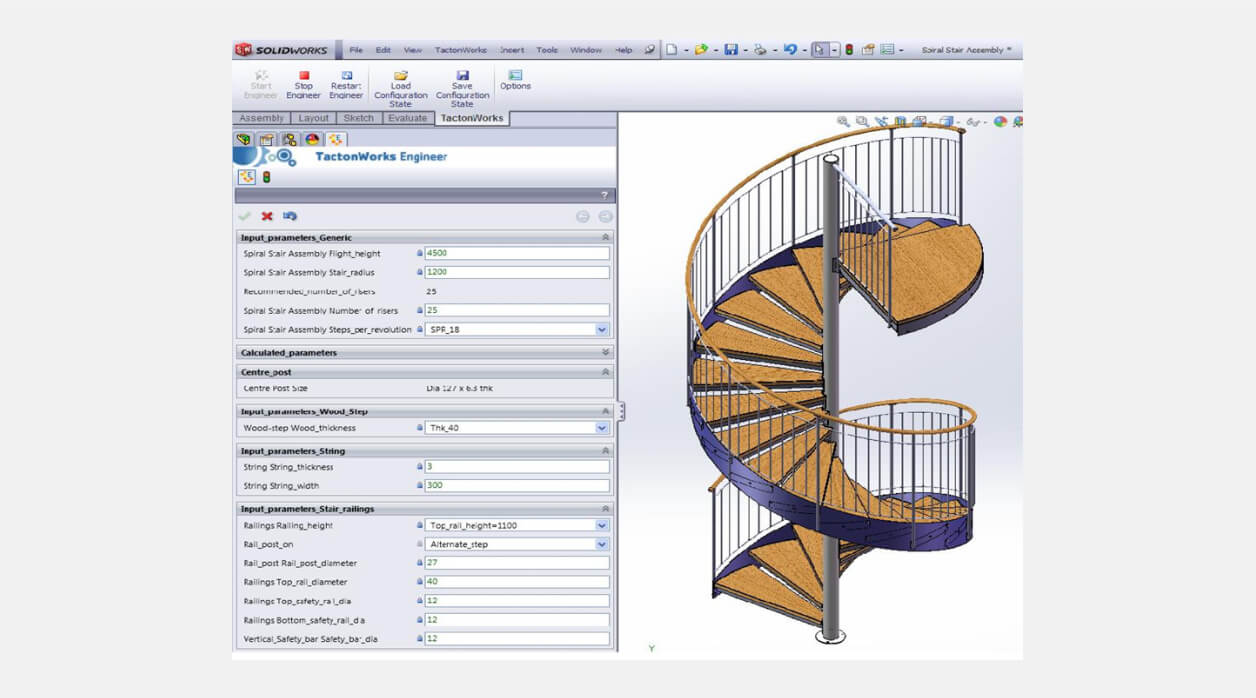

We collaborated closely with subject matter and calculation experts to bring this critical system to life. Our scope covered everything from detailed design and engineering calculations to 3D parametric modeling.

We also conducted CFD analysis for the mud-gun barrel and nozzle, and developed comprehensive Erection, Operation & Maintenance manuals. Additionally, we delivered quality assurance plans and P&ID schematics in DWG format for seamless execution.