TRANSPORTATION

Today’s cars are giant sensors on wheels. Technological advances—including interactive safety systems, vehicle connectivity, and, ultimately, cars that drive themselves-have changed the game. At Tooltech we aid this evolution. Our capabilities span right from Mechanical engineering, Electrical engineering to Instrumentation & Controls and Embedded systems.

ELECTRONICS

Manufacturing Engineering

In addition to this we have capabilities across CAD and Simulation

At Tooltech, along with our partner Hörmann, we have a large body of work, both specific design-build and turnkey, across 69 projects. We execute in a seamless mix model, combing the best of knowhow, experience and competitiveness, while taking full project responsibility.

SERVICES WE OFFER

Our services include total vehicle knowhow, train engineering – coaches and locomotives, testing and SOP, analysis and synthesis, concept and strategy. Transfer of technology, production and manufacturing engineering with handholding is our forte. At any time, we are designing, conceiving, closing, or are in the middle of three or four projects, globally.

In India, we are currently doing bogie design, interior and exterior design engineering for Indian Railways.

LOCOMOTIVES

METROS

DOUBLE DECK TRAINS

LIGHT RAIL VEHICLES

HIGH SPEED TRAINS

SPECIAL VEHICLES

MULTIPLE UNITS

BOGIE

USER INTERFACE ENGINEERING

Our expertise in the design segment encompasses creative and innovative concept design, optimized basic design supported by regulatory and client requirements, as well as integration and coordination of detailed design. We cater to the most up-to-date software and techniques for development of 2D & 3D designs.

|  |  |  |

| DETAILED ENGINEERING | CLASS DRAWINGS/ STATUTORY PLANS | PROJECT COORDINATION | MARINE EQUIPMENT |

State of the art experience in Detail Engineering of Hull and Outfitting segment of Cruise liner vessels Hull Detail Design: Outfitting Detail Design: Interior Detail Design: Design Automation Applications: RETROFIT / CONVERSIONS: | Well conversant with global classification societies standards and in a position to deliver required class drawing layouts for equipment arrangement plans, safety plans in line with SOLAS rules and SOLAS calculations for combustible materials. | Sound knowledge of integration and coordination of basic design with detailed design & production design We assist the client in liaising, assessing material specification conformity, carrying out compliance checks with respect to contract requirements and in the co-ordination of detail design with production team. | Expertise in 3D parametric modelling & detail engineering of various marine equipments like hatch cover, deck crane, winch and ramp doors. |

SOFTWARE

Good aerospace interior design is not merely interior decoration. A well designed aircraft cabin interior provides a unique ‘inflight experience and fulfilment’. At Tooltech, we endeavour to offer complete end-to-end solutions, from concept to product, in the area of composites, which will help our clients deliver a unique in-flight experience.

SERVICES WE OFFER

CASE STUDIES

CASE 1

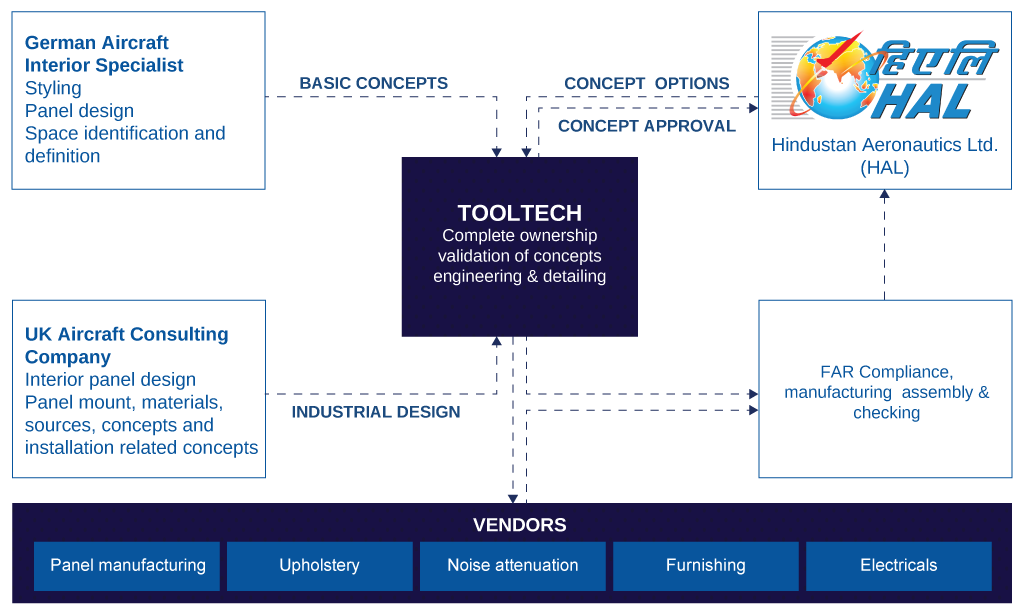

INTERIOR DESIGN AND PROTOTYPE OF VVIP HELICOPTER

The only ‘makeover’ single party design contract given by HAL to a private company to redefine its product.

Concept:

Complete design & prototype of a “World Class” VVIP helicopter interior (in compliance with FAR Part 29) at a fraction of the international cost of a military helicopter

Objective:

End-to-end project management from concept to final finished interiors

Inclusive of concept design, interior styling, weight optimization, detailed development, cabin noise reduction.

Deliverables:

Total design knowhow

Furnished panels for cabin, pilot and sliding doors, furnishing in cargo area and cock pit, lighting & air vents accessories, informative signs, carpet, side ledges

PROJECT EXECUTION

SERVICES WE OFFER

METRO OPERATORS

| Consulting | Engineering | Implementation |

We offer consulting services to support the completion of a diverse range of projects across upstream downstream processes. PMC: Project Management Consultancy (GC: General Consultants) DDC: Detailed Design ConsultancyDPR: Detailed Project Report Consultancy In India, we are currently working on a feasibility study and factory planning for Maha Metro’s Rolling Stock factory; besides advising them on Rolling Stock procurement and strategy including the DPR. | Along with Hörmann Vehicle Engineering GmbH, our engineering teams are competent to provide customised services Tailor-made to each city’s architecture and engineered product Industrial design, styling & rendering to match the city’s culture and needs Product design, including detailed design engineering | Where consulting meets engineering – across procurement, commissioning and start-up – we provide comprehensive organisational and project related support throughout all implementation phases, to ensure maximum satisfaction. Tendering, bid management and procurement Product realisation, knowhow, transfer of technology Infrastructure (factory, depot, maintenance yard etc) design, process planning and production Compliance (RAMS, test plan, approval, certification & technical documentation) |

ROLLING STOCK OEMS

Product Facelifts and fresh modern, distinctive design of Rolling Stock

Design Study – An extensive output of first design visualizations

- Value Added Value Engineering (VAVE) in subsystem for continuous improvement

- Carbody (Underfloor, door, coupler, sidewall, roof & cab-end)

- Machinery, pneumatic brake system & pantograph

- Facility (Interior, exterior & HVAC)

- Bogie (Design, analysis and validation)

- Electric system and equipment including wiring & cabling

- Applied technology (Structural analysis, NVH & kinematic envelope)

Project Engineering Management – Complete and transparent control to ensure timely delivery of quality service with cost effectiveness

Product Realisation & Factory Planning

- Technical assistance on indigenising

- Process plan and process engineering

- Lean layout to optimize the space

- Prepare plant machinery and equipment list

- Tooling, jigs and fixture planning

- Tendering support, commercial negotiations and equipment procurement

Factory AutomationActivities include feasibility studies, best-fit specifications and concepts, hardware and software design, robot implementation and installation, start-up and training services

Pre-bid Support

- Engineering proposal assistance and Conceptual design

- GA for Bogie & Cab Car

- Carbody Structural diagram

- Undercar Equipment arrangement

- Cab & Console layout

- Floor Plans