MANUFACTURING ENGINEERING

ENERGISING

MANUFACTURING

PROCESSES

Factory 4.0 needs sophisticated infrastructure and robotic integration. Equipments need to talk to each other. Equipment has to talk to a gantry, which has to talk to the next gantry and so on. Grippers, fixtures, machine tools all need holistic multi disciplinary engineering integration. We deliver this from our office and at your site – anywhere, in the world. In doing so, we drive your innovation.

SERVICES WE OFFER

TOOL

DESIGN

JIGS &

FIXTURES

BIW

FIXTURES

ROBOTIC OFFLINE

PROGRAMMING

ASSEMBLY ENGINEERING & ASSEMBLY LINE AUTOMATION

PROCESS PLANNING &

OPTIMISATION

EMBEDDED SYSTEM

ELECTRICAL & CONTROLS

SOFTWARES

DESIGN

AUTOCAD

INVENTOR

SIEMENS NX

CREO

SOLIDWORKS

SOLIDEDGE

CATIA

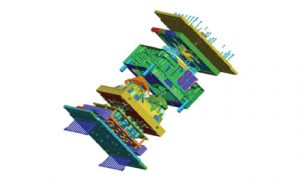

ANALYSIS

ANSYS

ANSA

HYPERMESH

ANIMATOR

ABACUS

LS-DYNA

FLUENT

FE-SAFE

FEMFAT

MODEFRONTIER

STAR-CCM+

GAMBIT

VERTICALS WE CATER

INDUSTRIAL EQUIPMENT

& MACHINERY

AGRICULTURAL

EQUIPMENT

CONSTRUCTION

MACHINERY

FOREST

MINING

MATERIAL

HANDLING

SPM

PROCESS &

CHEMICAL INDUSTRIES

AUTOMOTIVE

CASE STUDIES

CASE 1

A leading European leader in the areas of heat transfer, separation and fluid handling was looking for partnership for press tool design. The skeleton method of component design was followed to make the heat exchanger plates & press tool designs.

CASE 2

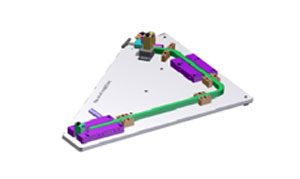

We designed & developed a checking fixture for seamless tube structures for the largest contract tubing manufacturer in North America. Tooltech developed the concepts, 3D design & 2D manufacturing drawings on the basis of the drawings of components & basic requirement of checking fixtures provided by the client.

CASE 3

The client, a manufacturer of plastic injection and die cast molds, was looking for partnership in the area of mold design. One of Tooltech’s engineers was trained onsite on the clients work methodology, best practices and standards. The offshore team had to work concurrently with their manufacturing cycle as