AI- Powered Extreme Weather Vision, Signal Colour, Obstacle Detection & Pilot Assistance System

Reliable Visibility in Fog, Rain, Dust, and Darkness

Tooltech along with its long-term technology partner VTT Technical Research Centre of Finland. co-developed an AI-powered system with multispectral cameras, satellite positioning systems, and AI software that overcomes the limitations of both human vision and traditional automation—empowering loco pilots with real-time, all-weather visibility and critical decision-making support. The product is now also used in mining to address visibility issues caused by dust and heavy fog.

The Problem

Railway operations rely heavily on visual judgment. But what happens when visibility is compromised—due to fog, dust, heavy rain, snow, low light, or unexpected obstacles?

Some of the problems which loco pilots face are

Zero visibility in extreme conditions (fog, smoke, darkness)

No clarity of signals or tracks due to glare/blooming

Failure to detect obstacles within braking distance (livestock, debris, pedestrians)

Inability to ensure safety where track fencing or isolation is not feasible and most of the tracks in India are unmanned & unfenced.

The Product – Our Solution

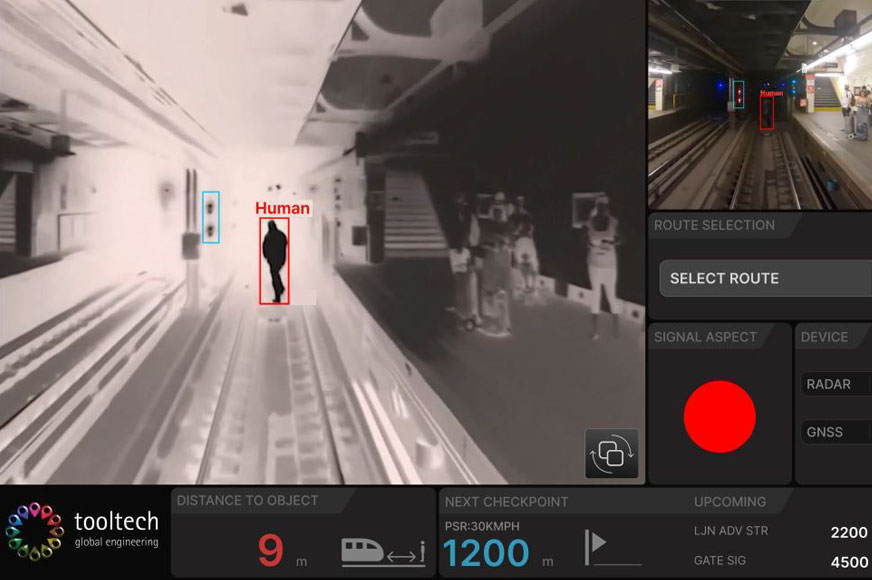

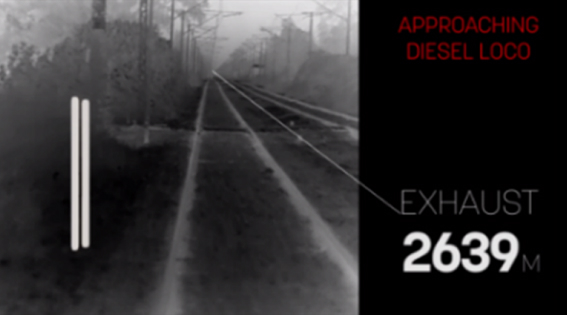

This cutting-edge technology which integrates radar, multi spectral cameras, satellite positioning data and AI software to enhance vision and assist the loco pilot. It gives loco pilots critical seconds to act—before the braking distance—and enhances their decision-making ability in real time.

The technology has been successfully tested on Indian railway tracks—many of which are unmanned and unfenced. These conditions often result in frequent crossings by people and animals, leading to a high risk of collisions. As a precaution, trains are forced to slow down, sometimes operating at speeds as low as 20 km/h.

These sensors work in tandem to provide real-time monitoring for operators with unparalleled situational awareness and hazard perception capabilities.

Some before & after images of railways trails

Unaided Human Vision

Naked eye view when train is approaching

Naked eye view from the cab which is unclear

Naked eye view at nighttime

System-enhanced Vision

Clear view through the system

View through the system

Signals detected with neural networks

There is huge potential in adapting this technology across domains. One such area is mining where the needs are both unique and overlapping.

Mining operations require wide-angle coverage of the entire site rather than a long 2 km track view, along with exceptional night-time / heavy dust vision clarity and resilience to prevent slowdowns or shutdowns.

At the same time, both railways and mining share critical requirements: all-weather visibility for safe operations, clear signal detection, and reliable collision avoidance—whether with people, animals, or heavy equipment.

Trials in active Indian mine sites have demonstrated the system’s ability to enhance driver awareness, boost safety, and maintain throughput even in challenging real-world conditions.

Unaided Human Vision

Naked eye view with low visibility

Visual as seen with the naked eye, where only one truck is visible

System-enhanced Vision

View through the system – Person & vehicle visible

View from the system, where two trucks are clearly visible

Advantages

At a Glance

Long Range Detection

Detects obstructions before braking distance up to 1.2 km away, providing ample time for locomotive pilots to react.

Obstruction Detection

Detects and recognise obstructions, to prevent potential collisions.

Collision Warnings

Alerts locomotive pilots in real-time of impending hazards, enabling accident prevention.

Visibility in Total Darkness

No dependency on ambient light.

High Distance Accuracy

Offers distance accuracy of Far Range - ± 0.40m and Near Range - ± 0.10m

HD Display

Rugged high-definition display with touch screen functionality for easy interaction.

Mechanical Vibration Resistance

Vibration & shock proof - Built to withstand mechanical vibrations commonly experienced in railway environments ensuring consistent performance and durability.

Narrow Field of view (NFOV)

Narrow Field of view (NFOV)

Allows distant objects to be seen from more than 1200 meters away.

Wide Field of view (WFOV)

Can see the immediate area, allowing obstacles & signal lights to be detected from a wide area near the locomotive. Our wide field of view camera provides exceptional coverage of the track ahead, delivering complete visibility of the areas alongside the track.

Integrative Data Processing

Combines inputs from multiple sensors to provide real-time alerts.

Energy Efficient

Power consumption less than 100 Watts