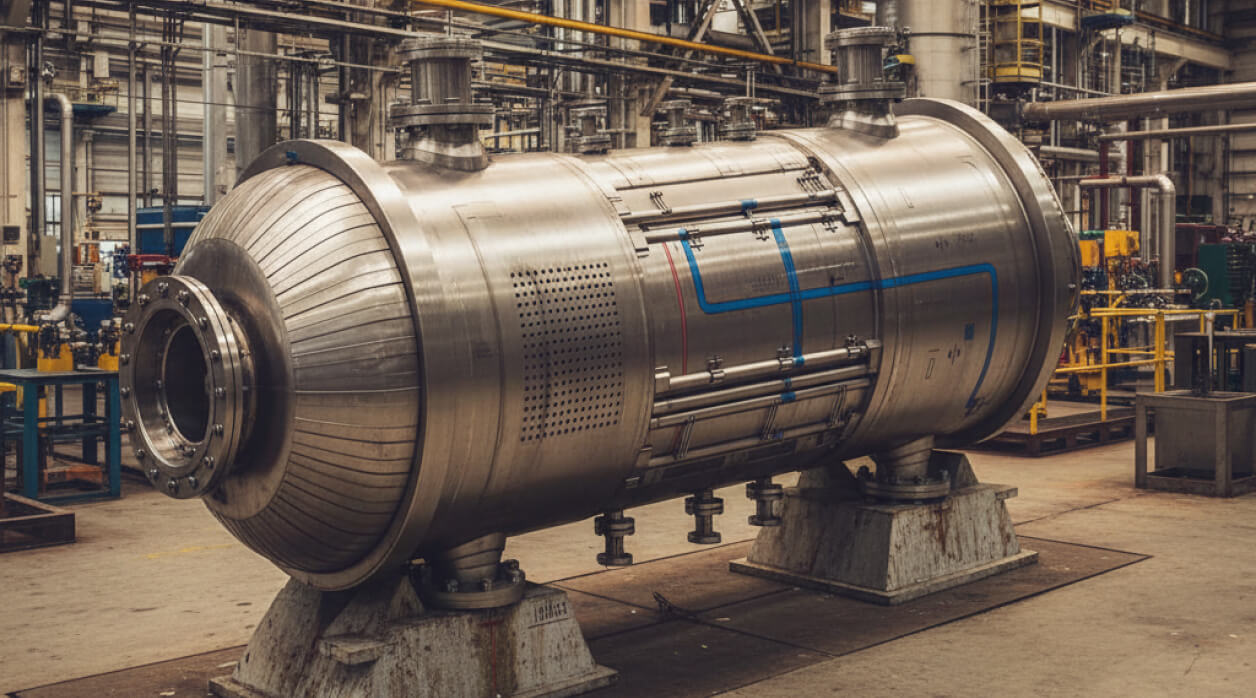

We assisted in converting a non-pressurized mixing barrel into a pressure vessel while ensuring compliance with PED standards. Using ANSYS 2020R1, the project involved finite element modeling, stress analysis, and deformation evaluation. The analysis confirmed maximum deformations of 0.16mm (test pressure) and 0.08mm (working pressure), with Von-Mises stresses within.

Conversion Of Non – Pressurised Mixing Barrel Into A Pressure Vessel