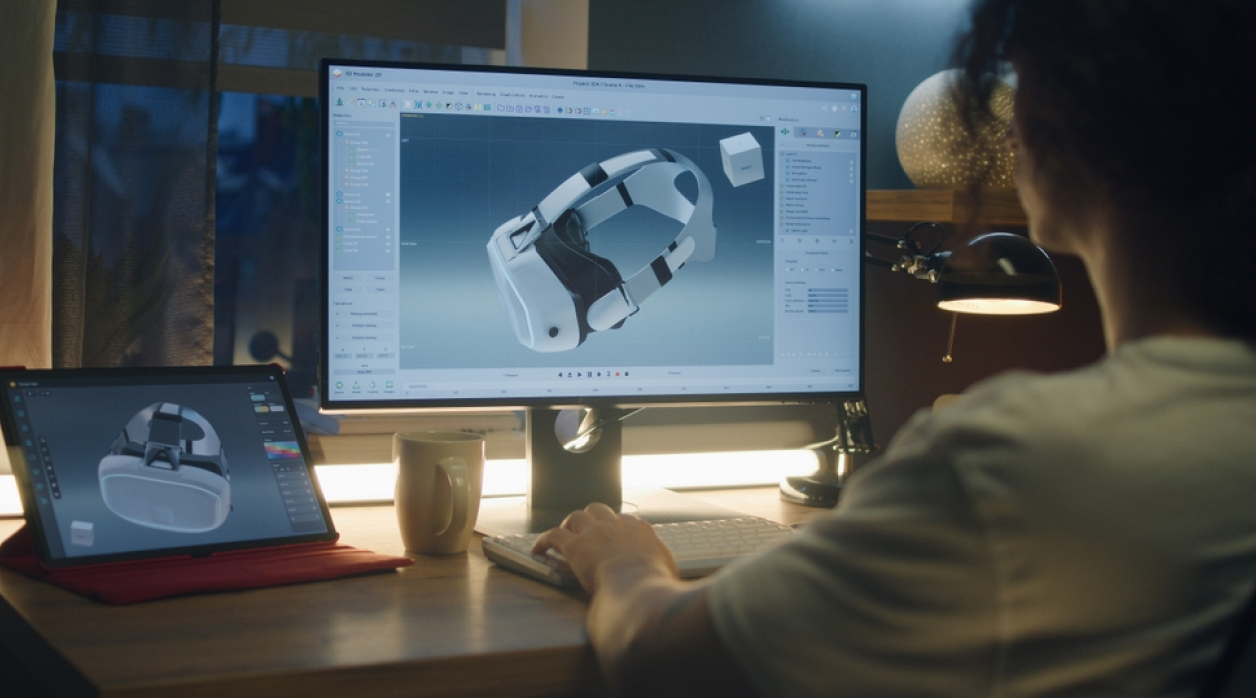

A Scandinavian welding solutions manufacturer approached us with design optimization and localisation of their automated welding machine. We designed the PCBs for the UI membrane panel, integrated main circuit and EMC filter making some design changes in the process. We also designed the schematics for the main circuit board and the UI membrane. The secondary diode PCB was removed and components placed on the heatsink. We re-looked at the assembly and re-arranged various parts so that heatsink commonisation could be achieved. We also suggested the replacement of few parts with functionally optimum & cost-effective options. The mechanical assembly was redesigned with respect to changes made and client’s specifications.

PCB Design & Localization For An Automated Welding Equipment