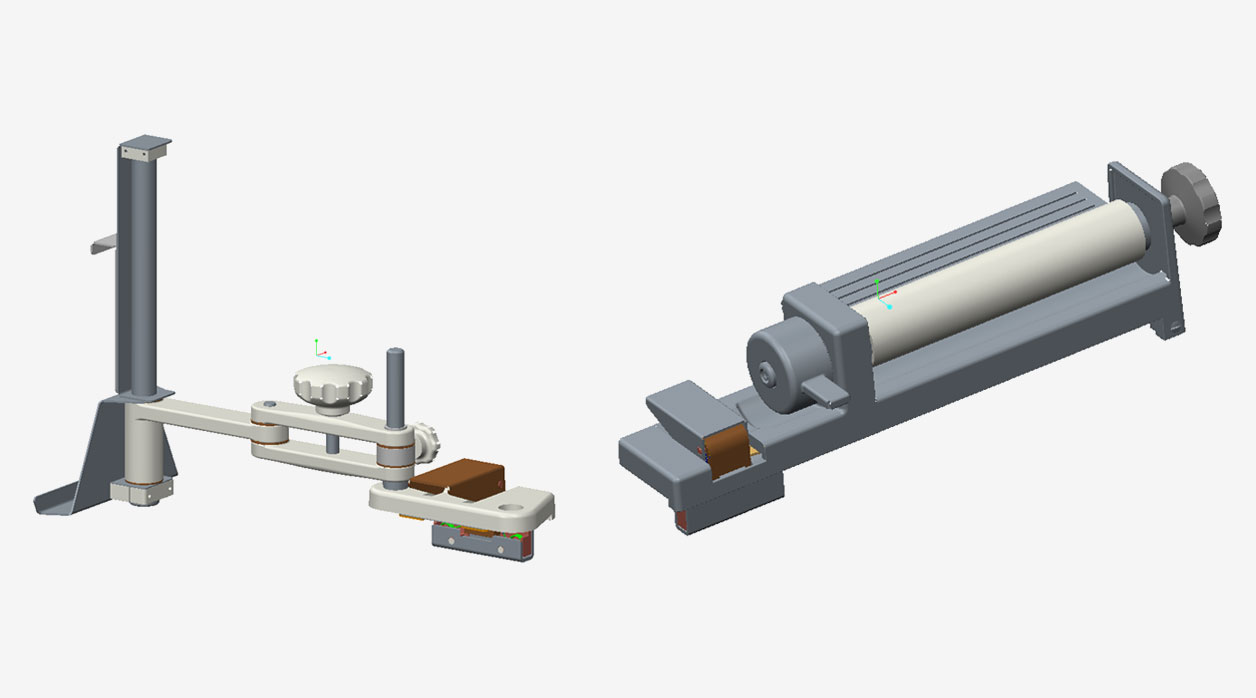

We worked on reverse engineering of diagnostic machines accessories for a leading healthcare manufacturer. We were given physical samples as no design data was available. The challenge was in dismantling the product without any damages and ascertaining precise dimensions for worn out parts. A 3D laser scanner was used to identify dimensions. We studied the product right from the assembly down to each part in detail to decide the design and manufacturing specifications.

The assembly structure and models were created in 3D environment with respect to clients various catalogues so that any future changes could be accommodated. Wherever possible we used standard items from the clients library. We provided the client with the 3D model of the Assembly, 2D manufacturing drawings with information on selection of appropriate tolerances, surface finish, surface treatment and material and BOM.