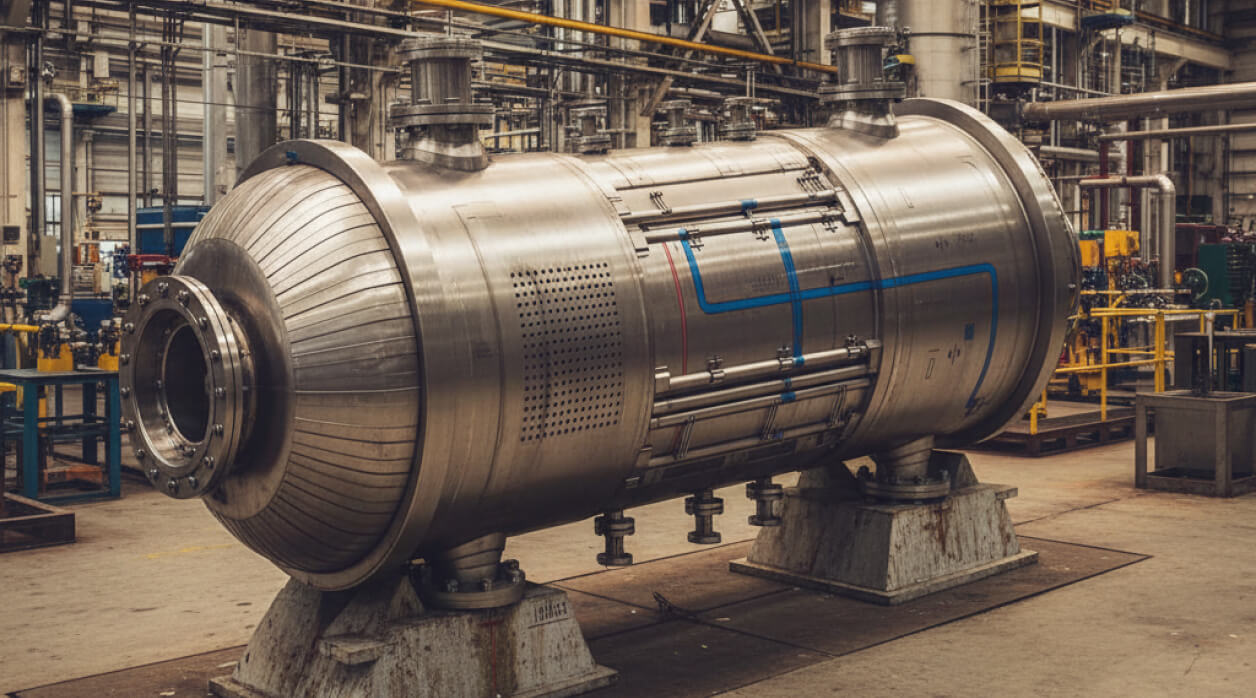

For a leading automotive OEM, we worked path programming for robotic welding, in a door closure manufacturing line. The project involved spot welding, handling, gluing, and cutting applications for front and rear door lines, using KUKA robots (KR210, KR310, KR1000, KR420) and KRC-2/KRC-4 controllers. We optimized robot paths, ensured collision avoidance, I/O configuration, and PLC integration, and conducted auto trials for production and quality proving. The program standardization enhanced flexible manufacturing and efficiency.

Path Programming For Robotic Welding In Door Closure Line