Automotive Engineering Services

End-to-End Automotive Product Engineering for the Next-Gen Mobility.

Tooltech Global Engineering is a trusted partner to global automotive OEMs and Tier 1 suppliers, offering comprehensive automotive engineering services that span concept, design, development, and manufacturing. From internal combustion to electric and hybrid vehicles, we help our clients accelerate innovation, reduce time-to-market, and achieve competitive advantage.

Our Core Automotive

Engineering Capabilities

Full Vehicle Product Engineering

We provide end-to-end vehicle development services, supporting automotive programs from initial concept to production launch:

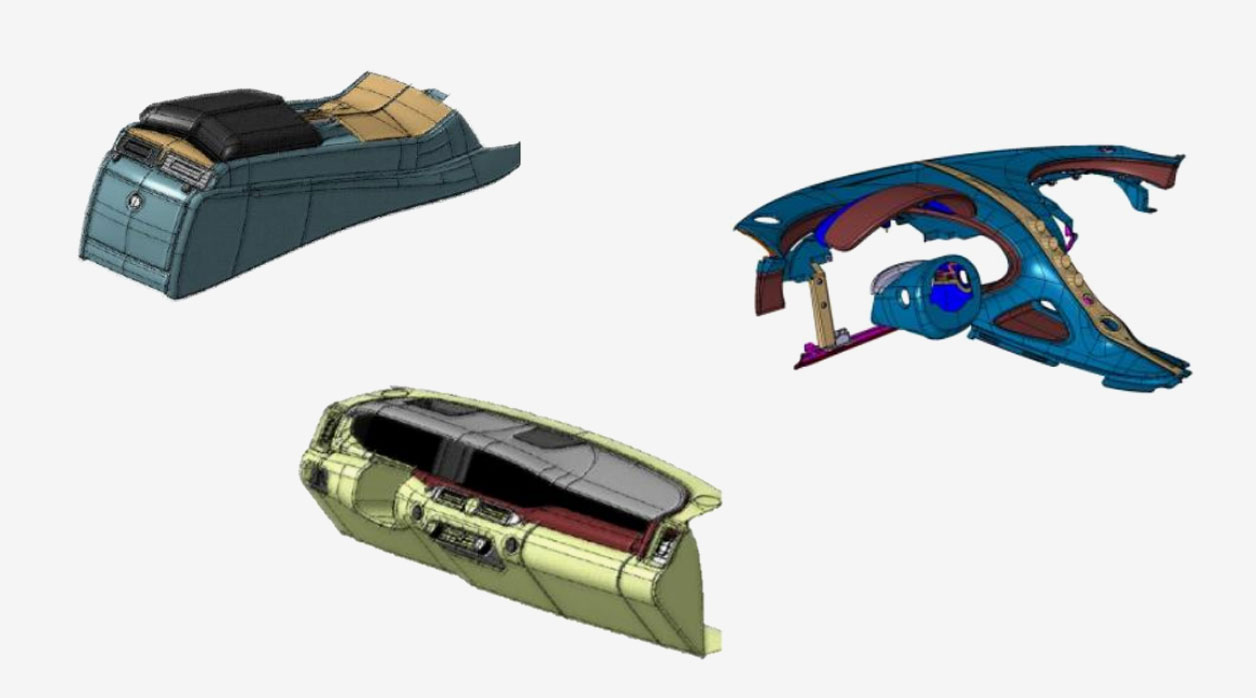

CAD modelling

- Body-in-white & closures

- Interior trim

- Seating

- Roof

- Front end system

- Underbody & BIW frame

- Chassis

- Chassis frame

- Hydraulic piping

- Fuel tanks

- Powertrain

- Class A Surface

- Hybrid & EV Car Design

- Manufacturing Feasibility

- Electrical / Electronics

- Connected & automated Driving

- V2X

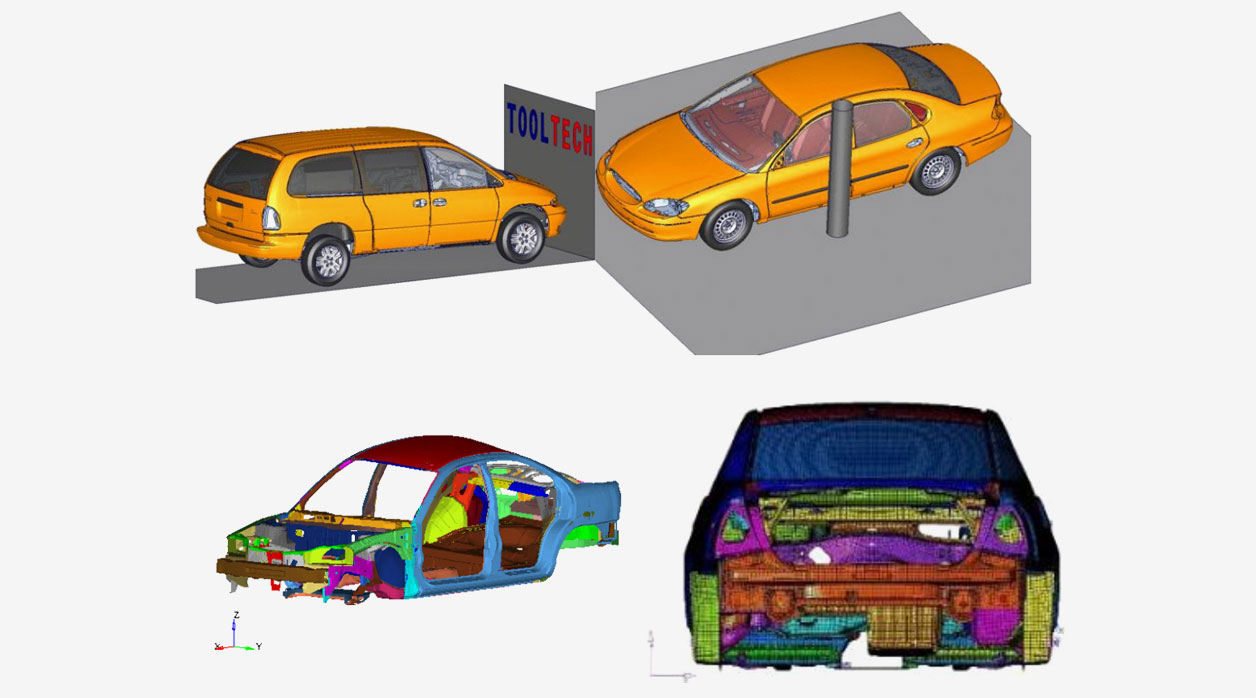

CAE & Simulation (Validation)

- FE – Modelling (2D,3D)

- Analysis

- Crash Analysis

- Full Vehicle

- Sub Level System – Interiors, Seatings,etc

- Strength Analysis

- Pedestrian Safety

- NVH Simulation

- Material Testing

- Thermal Simulation

- Engine Simulation

- Crash Analysis

- Systems engineering & full vehicle integration

- Validation & product testing support

Embedded Software & ADAS Development

We design and integrate embedded systems for connected and autonomous vehicles:

- Advanced Driver Assistance Systems (ADAS) development

- In-vehicle infotainment (IVI) HMI engineering

- Telematics, V2X communication, and FOTA updates

- AUTOSAR-compliant software development

- Functional safety (ISO 26262) cybersecurity

Manufacturing Engineering

Accelerate your digital transformation with our Industry 4.0-enabled engineering services

- Tooling Design

- Plastic Sheet metal tooling design

- Fixtures Automation tooling design

- BIW welding fixtures

- Grippers

- CO2 welding fixtures

- Checking / Inspection fixtures

- Assembly fixtures

- Machining fixtures

- Material handling equipment – Racks Carts

- Robotic offline programming

- Production Planning Layout

- Assembly stations

- Gantry lines (machines subsystems)

- BIW production cells

- Robotic cells

- Machining fixtures

- Grippers loading arms

- Gun stations

- Electric Vehicle (EV) Station Design

- Stator and rotor assembly

- Battery assembly (Cell / Module / Pack)

- Powertrain assembly

- In-process and End-of-line (EOL) quality stations

- Technical Documentation (OEM Specific)

- 3D CAD Documentation (CATIA/NX/AutoCAD)

- Digital Mock-up

- Process Documentation

- Electrical Design Design

- Electrical/Fluid/Hydraulics schematics load calculations

- Control panel starter layout

- Drive systems wire harnesses

- Cable routing tray design

- Equipment selection safety setup

- On-site commissioning support

- PLC/CNC Controls

- System architecture component choice

- PLC, SCADA, CNC integration

- HMI development

- Safety logic field bus config

- Remote control diagnostics

- PLC upgrades, robotics setup

- Robotic Simulation

- Weld Spot Distribution

- Robotic Reachability

- Welding Feasibility

- Offline Programming

- Supplier onboarding and RFQ management platforms