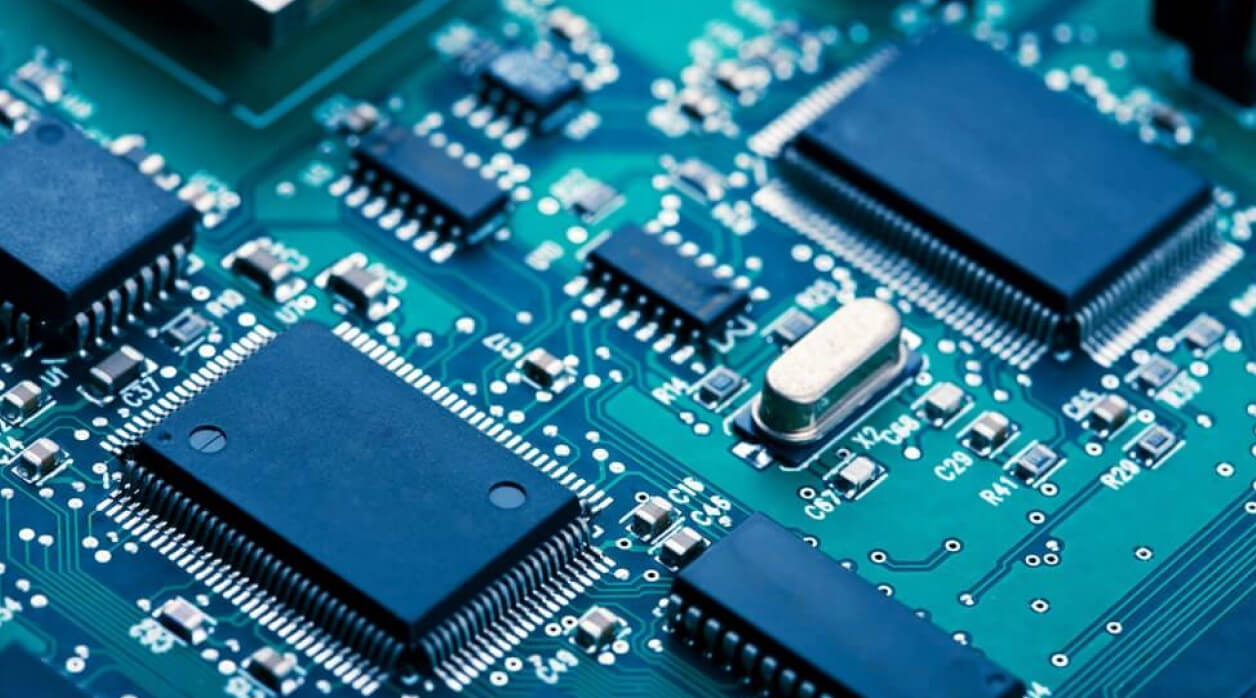

We played a key role in a blue-sky project, developing a fully automated shipment measurement system. Our involment in the project spanned across hardware design and detailing, software development & integration. The software system uses 3D imaging with a Time-of-Flight camera to measure parcels with ±5mm accuracy for weights up to 200 kg. We developed the interface software in C++ and Visual Studio, enabling barcode/QR scanning, weight capture, and dimensional analysis. The collected data enabled automated sorting, cargo freight forwarding, and warehouse management. The project progressed from concept to prototype in just eight months, demonstrating rapid development and prototyping capabilities.

Application Development & New Product Development For Shipment Measurement System

Other Case Studies