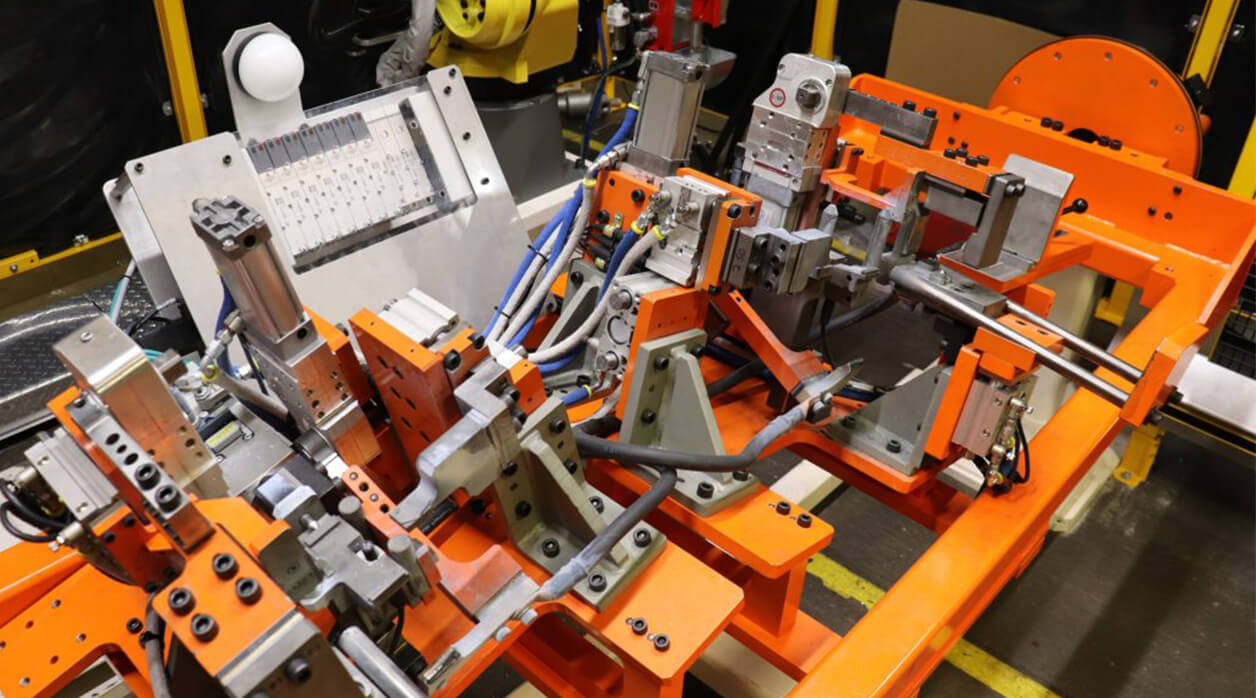

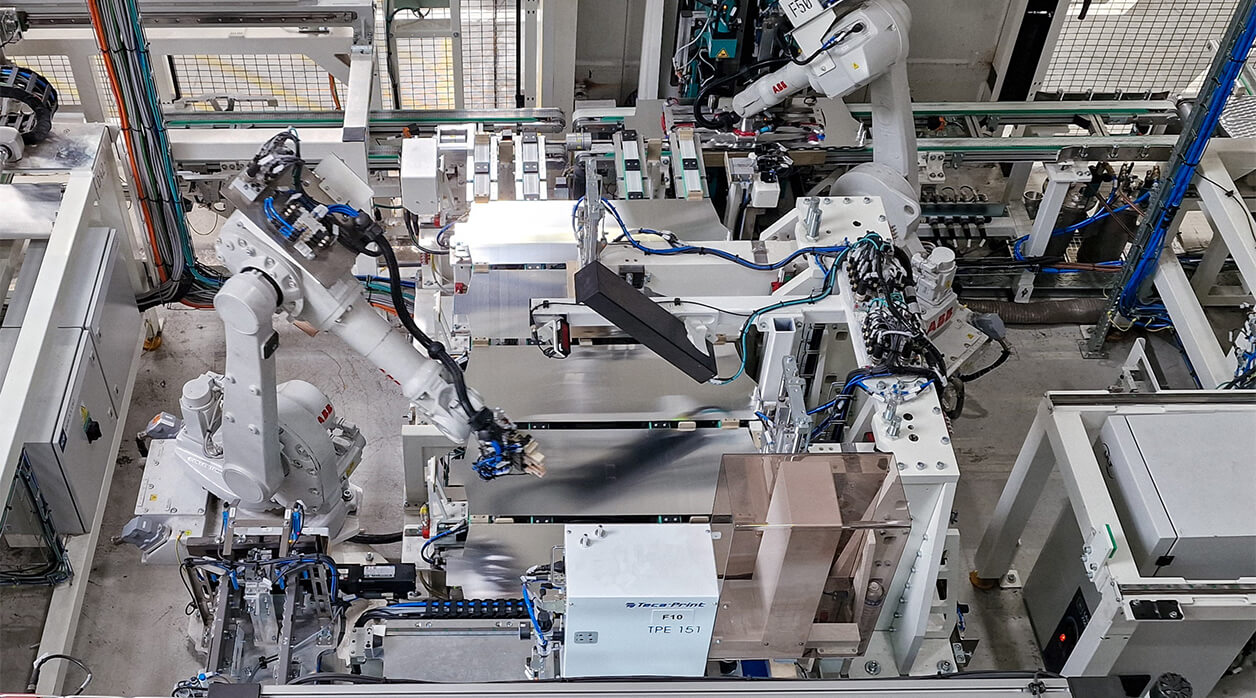

Tooltech executed the installation, commissioning, production support, and debugging for a cylinder block and head machining line at a leading truck manufacturer’s powertrain plant. The project involved OCR station setup, laser marking, gantry integration, conveyor system commissioning, safety interlock validation, and PLC program optimization. Key tasks included gantry temperature compensation, SPC station programming, machine interface setup, and automatic cycle sequence validation. Using Siemens Sinumerik 840D SL, Profibus DP, Cognex scanners, and laser marking systems, Tooltech ensured seamless automation, efficient part tracking, and optimized production workflows.

CNC Machining Line Automation For Cylinder Blocks Of A Heavy-duty Pickup Truck