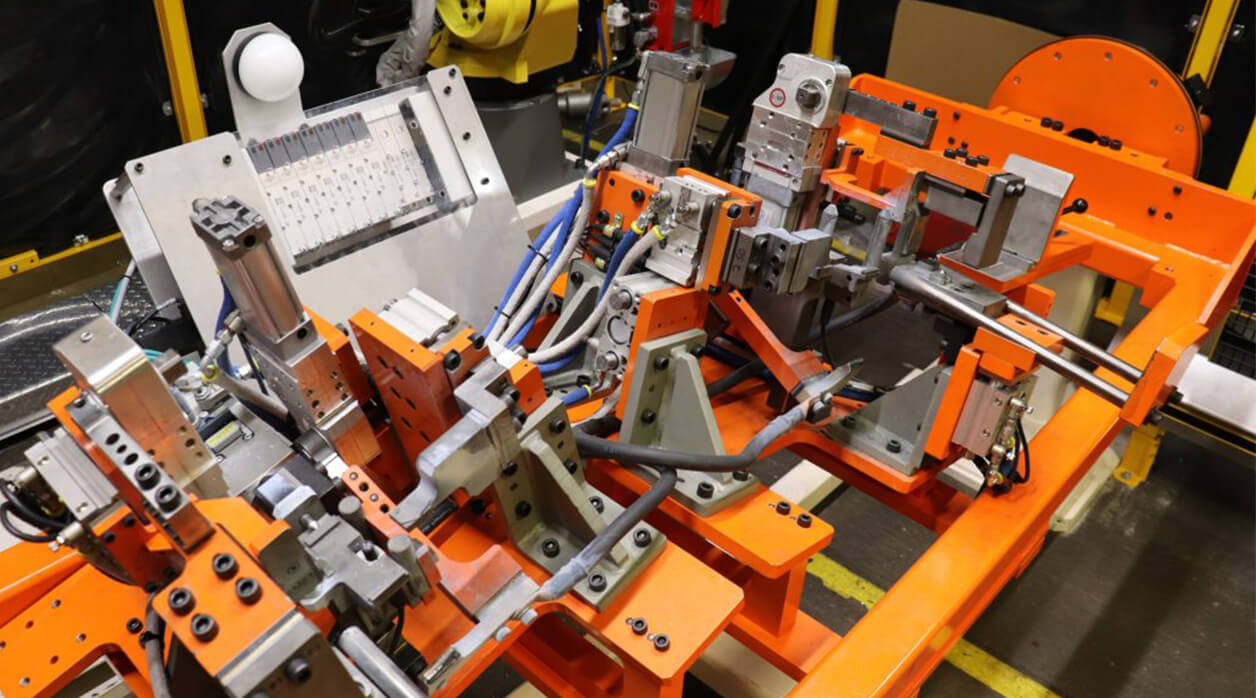

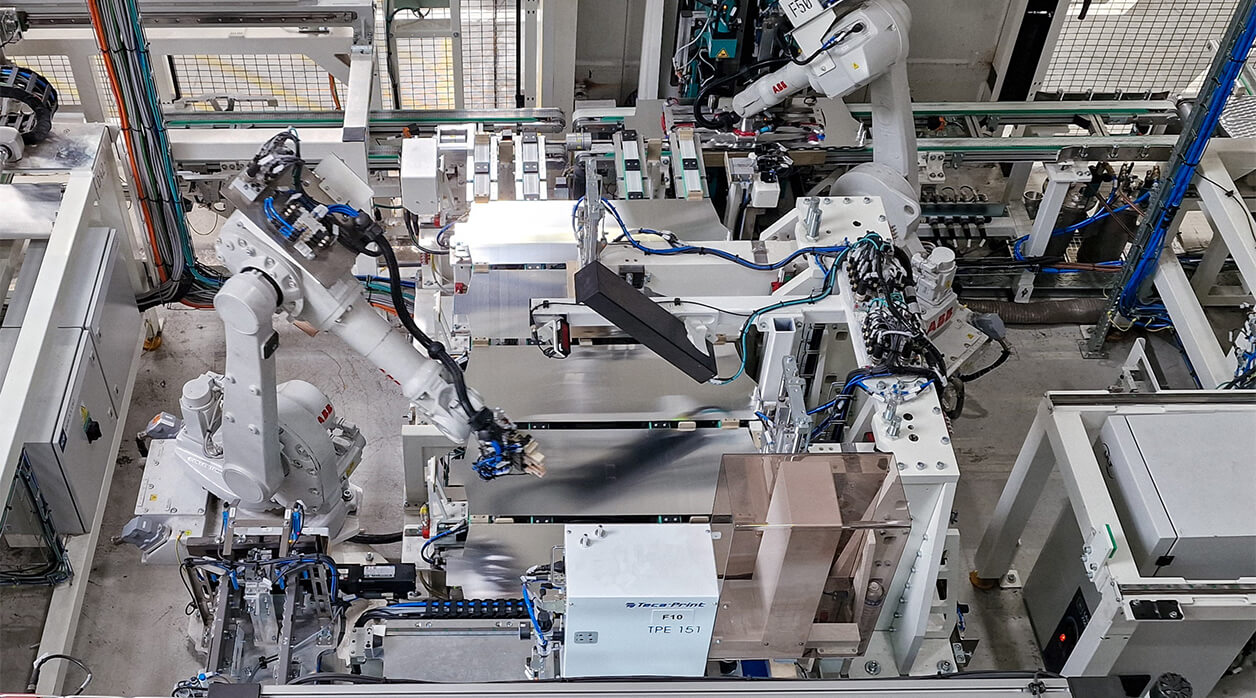

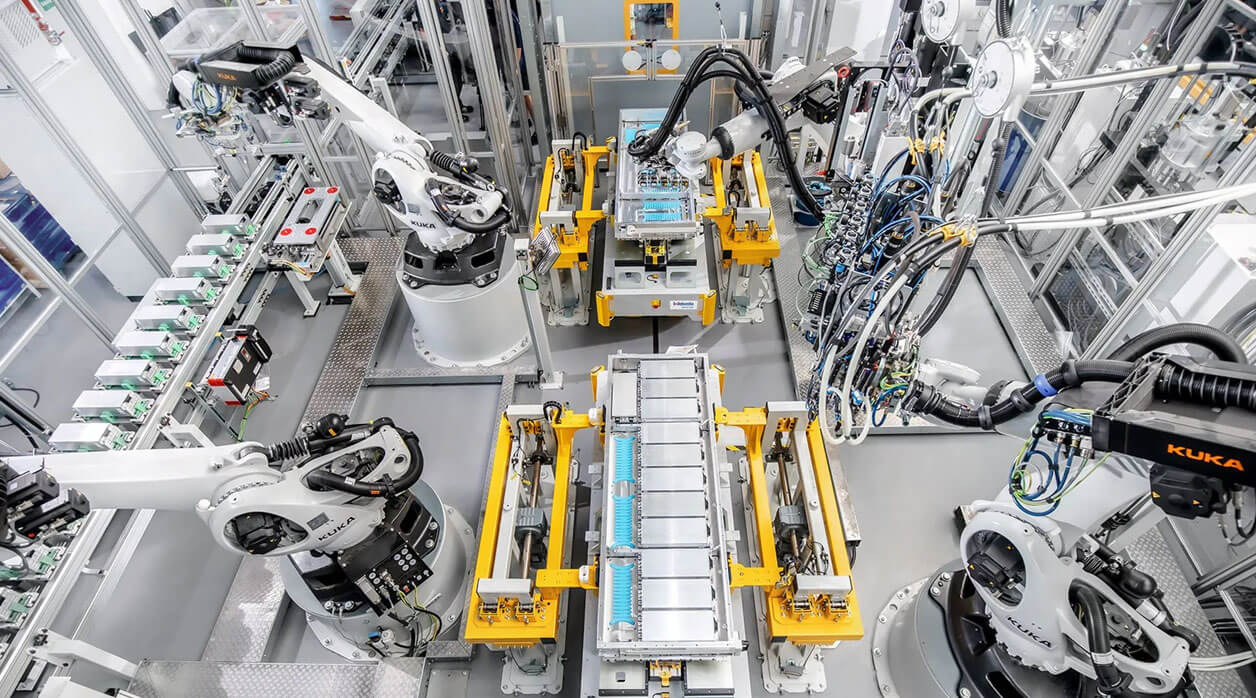

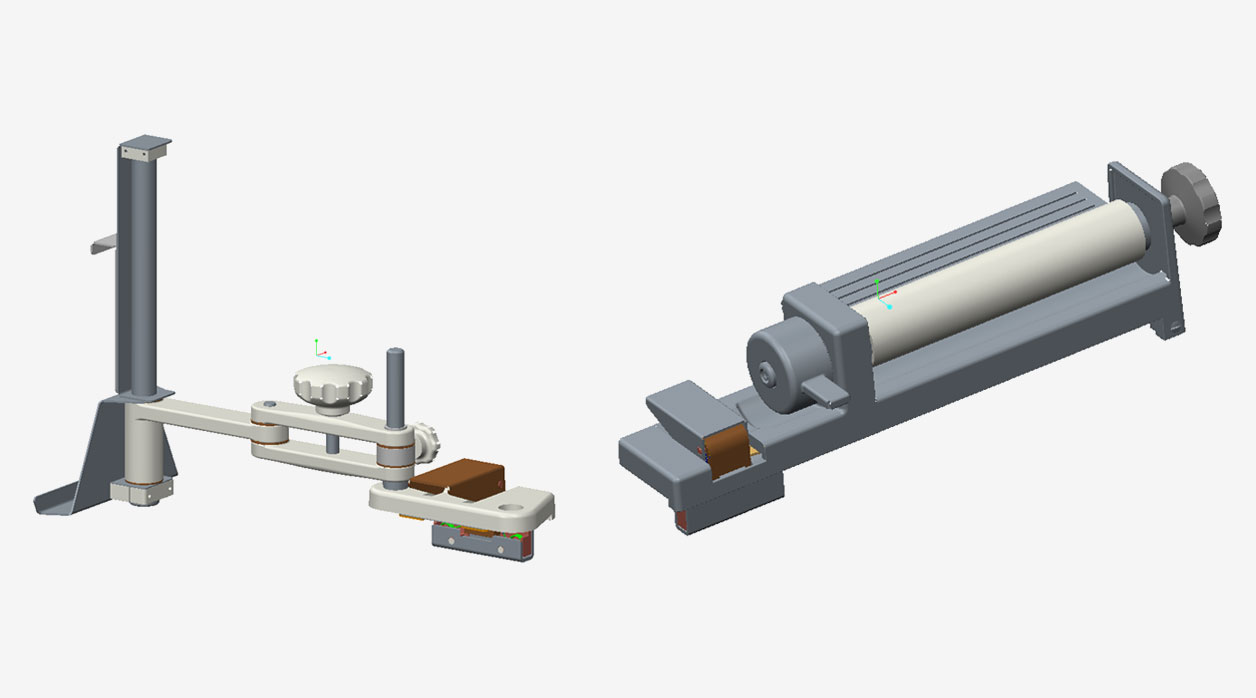

We executed the 3D concept design, 2D manufacturing drawings, and BOM preparation for robotic BIW fixtures featuring pneumatic clamping and part presence sensors. The project involved riveting, sealing, and MIG welding for key assemblies such as the wheelhouse, windshield, and sealing channel rear assembly. Using CATIA V5 R24, Tooltech adhered to client standards, ensuring precision and seamless integration within the robotic cell layout.

Robotic BIW Fixture Design & Detailing